OEM axial fan motors operating in the 500-3000 RPM range deliver reliable air movement for industrial and commercial applications. These motors feature built-in thermal overload protection to prevent damage from overheating during continuous operation.

OEM axial fan motors with thermal overload protection provide consistent performance while safeguarding equipment from heat-related failures that could cause costly downtime. OEM fan and blower motors are specifically designed to offer original equipment manufacturer replacements with automatic overload protection features.

The RPM range of 500-3000 allows these motors to match specific airflow requirements across different applications. Axial fans with direct-drive motors simplify configurations and reduce maintenance needs compared to belt-driven systems.

Key Takeaways

- OEM axial fan motors deliver thermal overload protection to prevent equipment damage and reduce maintenance costs

- The 500-3000 RPM range provides flexibility to match specific airflow requirements for various industrial applications

- Proper motor selection based on RPM, protection features, and application requirements ensures optimal performance and longevity

OEM Axial Fan Motors: 500-3000 RPM Range and Thermal Overload Protection

OEM axial fan motors in the 500-3000 RPM range provide reliable airflow solutions with built-in thermal overload protection for industrial and commercial applications. These motors deliver consistent performance across various operating conditions while preventing costly equipment damage through automatic temperature monitoring.

Key Features and Specifications

OEM axial fan motors typically operate on single-phase or three-phase power systems. Voltage ratings commonly include 115V, 230V, and 460V configurations to match different electrical requirements.

Motor Power Ratings:

- 1/4 HP to 3/4 HP for standard applications

- 1 HP to 5 HP for heavy-duty industrial use

- Fractional horsepower options for lighter loads

The thermal overload protection feature automatically shuts down the motor when internal temperatures exceed safe operating limits. This protection system uses built-in thermal switches or external overload relays.

Frame sizes follow NEMA standards, with common configurations including 48Y, 56, and 143T frames. Pedestal fan motors with 1/2 HP ratings demonstrate typical specifications in this category.

Motor enclosures feature TEAO (Totally Enclosed Air Over) or ODP (Open Drip Proof) designs. IP54 ratings provide protection against dust and water spray in industrial environments.

Benefits of Thermal Overload Protection

Thermal overload protection prevents motor burnout caused by excessive current draw or high ambient temperatures. The system monitors winding temperatures and disconnects power when limits are exceeded.

This protection reduces maintenance costs by preventing catastrophic motor failures. Motors with thermal protection typically last 30-40% longer than unprotected units in demanding applications.

Protection Benefits:

- Automatic restart capability after cooling

- Prevents fire hazards from overheated windings

- Reduces unplanned downtime

- Extends motor service life

The thermal protection system responds within seconds to temperature spikes. Manual reset options allow technicians to investigate causes before restarting operations.

Insurance requirements often mandate thermal protection for motors in commercial buildings. This feature helps facilities meet safety codes and regulations.

RPM Range Applications and Suitability

The 500-1500 RPM range suits applications requiring high static pressure and moderate airflow. These speeds work well for exhaust fans, cooling towers, and ventilation systems with ductwork restrictions.

Medium-speed motors operating at 1500-2500 RPM balance airflow volume with pressure capabilities. They perform effectively in HVAC systems, industrial process cooling, and general ventilation applications.

High-speed operations from 2500-3000 RPM maximize airflow volume for applications with minimal static pressure. These speeds suit clean air applications and large area ventilation.

Application Examples:

- 500-1500 RPM: Exhaust systems, heat exchangers

- 1500-2500 RPM: HVAC equipment, process cooling

- 2500-3000 RPM: Warehouse ventilation, air circulation

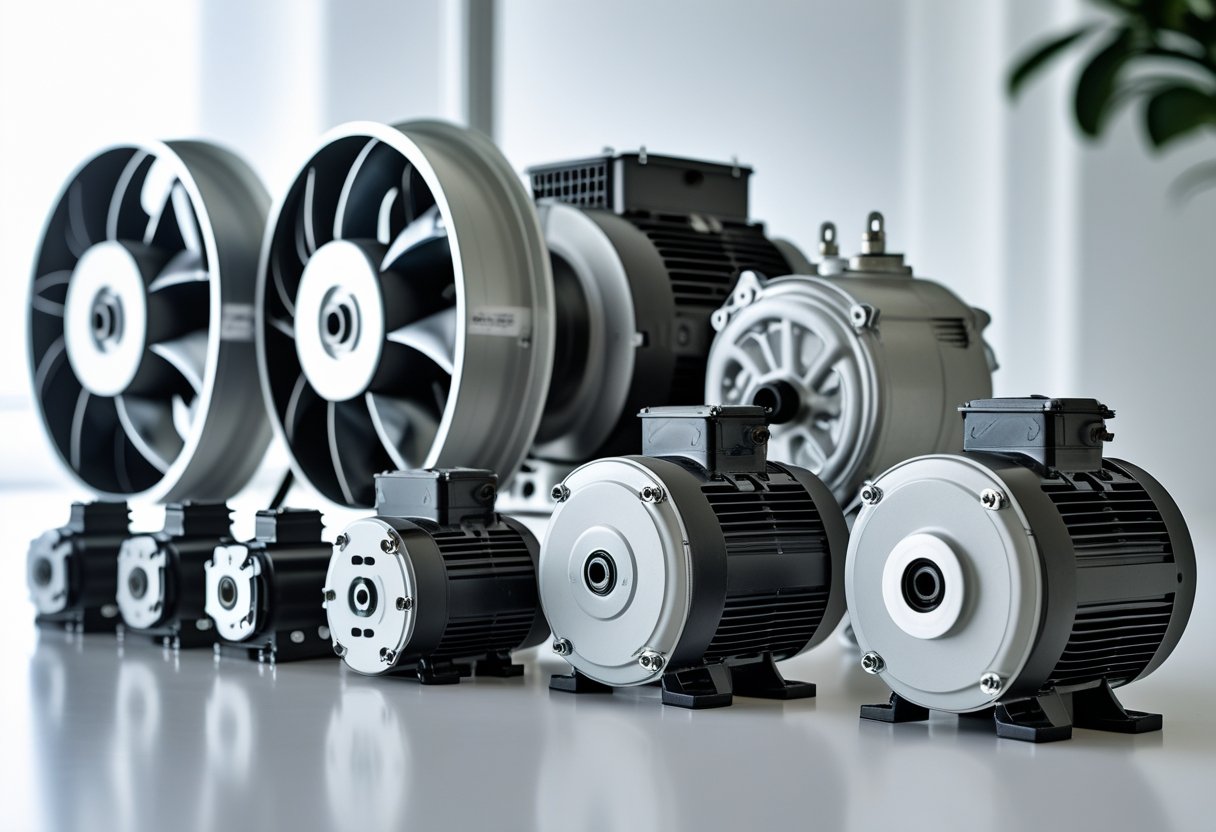

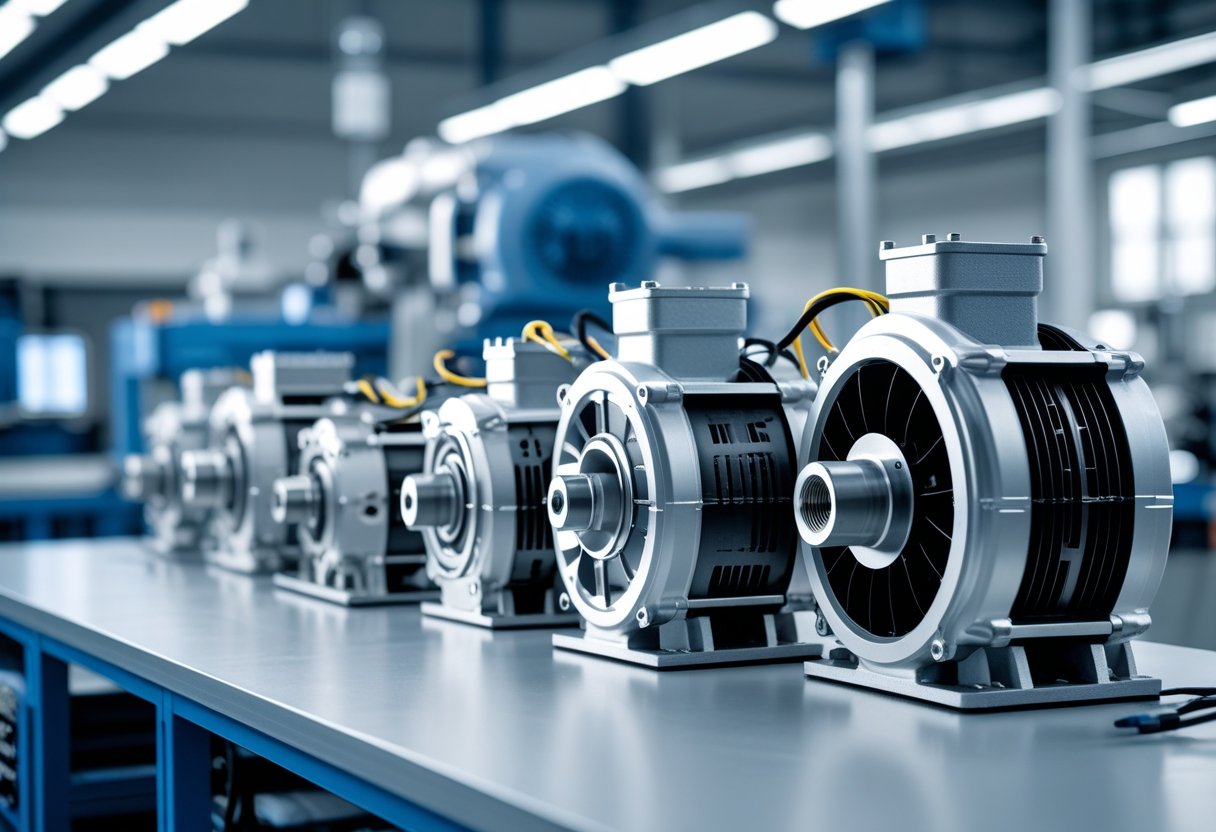

Industrial axial fans operating at various speeds demonstrate the range of applications across different RPM categories. Motor selection depends on system pressure requirements and desired airflow rates.

Essential Considerations for Selecting and Integrating Axial Fan Motors

Proper motor selection requires evaluating specific installation requirements, customization options, and performance characteristics. The 500-3000 RPM range offers flexibility for various applications while thermal overload protection ensures reliable operation.

Installation and Mounting Best Practices

Mounting orientation directly affects motor performance and lifespan. Horizontal mounting provides optimal bearing life for most axial fan motors. Vertical mounting requires special bearing configurations to handle thrust loads.

Vibration isolation prevents premature motor failure. Install rubber mounts or spring isolators between the motor and mounting surface. This reduces transmitted vibrations by up to 90%.

Clearance requirements ensure proper airflow and maintenance access. Maintain minimum 6-inch clearance around motor housing for cooling air circulation. Provide 18-inch access space for routine maintenance tasks.

Environmental protection matters for outdoor installations. Use NEMA 4 or IP65 rated enclosures in wet conditions. Install weatherproof conduit connections and drainage provisions for moisture control.

Custom OEM Solutions and Variants

Speed customization meets specific application demands. Motors can be wound for exact RPM requirements within the 500-3000 range. Custom speeds optimize airflow and reduce energy consumption by 15-20%.

Mounting configurations adapt to unique installations. Available options include:

- C-face mounting

- Foot mounting with drip-proof enclosures

- Flange mounting for direct coupling

- Custom bracket assemblies

Electrical modifications accommodate various power systems. Voltage options range from 115V single-phase to 575V three-phase. Motor selection complexity requires careful consideration of electrical specifications.

Special features enhance functionality. Options include variable frequency drive compatibility, explosion-proof ratings, and food-grade certifications for specific industries.

Efficiency and Reliability Factors

Thermal protection prevents costly failures. Built-in overload protection monitors winding temperature and automatically shuts down motors at 155°C. Reset capability allows quick restart after cooling.

Bearing selection impacts maintenance intervals. Premium sealed ball bearings provide 40,000-hour service life at rated speeds. Re-greasable bearings extend life to 60,000 hours with proper maintenance.

Motor efficiency ratings reduce operating costs. IE3 efficiency motors consume 10-15% less energy than standard motors. High-efficiency motors pay for themselves through energy savings within 2-3 years.

Quality construction ensures longevity. Features include:

- Class F insulation for high-temperature operation

- Corrosion-resistant finishes for harsh environments

- Precision-balanced rotors for smooth operation

- UL listed components for safety compliance

Frequently Asked Questions

OEM axial fan motors in the 500-3000 RPM range require specific features and considerations for optimal performance. Thermal overload protection plays a critical role in motor longevity and reliable operation across various industrial applications.

What features should I look for when selecting an OEM axial fan motor within the 500-3000 RPM range?

Key features include IP55 protection class for dust and moisture resistance. Universal fan motors with TEAO design provide enhanced durability in harsh environments.

Motor efficiency ratings directly impact operating costs. Variable speed capability allows precise airflow control within the RPM range.

Mounting options should match the specific application requirements. Ball bearing construction offers longer service life compared to sleeve bearings.

How does thermal overload protection benefit an axial fan motor’s operation and longevity?

Thermal overload protection prevents motor damage from excessive heat buildup. The protection system automatically shuts down the motor when internal temperatures exceed safe limits.

This feature extends motor lifespan by preventing winding damage. Motors can restart automatically once temperatures return to normal operating ranges.

Reduced maintenance costs result from fewer motor failures. Equipment downtime decreases significantly with proper thermal protection systems.

Can OEM axial fan motors with thermal overload protection work in high-ambient-temperature environments?

Motors with thermal overload protection operate effectively in elevated ambient temperatures. The protection system adjusts trip points based on environmental conditions.

Proper ventilation around the motor housing improves heat dissipation. Ambient temperatures up to 104°F typically pose no operational issues.

Motors may require derating in extreme temperature conditions. Consultation with manufacturers ensures proper selection for specific temperature ranges.

What are the energy efficiency implications of using axial fan motors in the specified RPM range?

The 500-3000 RPM range offers optimal efficiency for most axial fan applications. Lower RPM operation typically provides better energy efficiency ratios.

Motor efficiency peaks within specific load ranges. Proper sizing ensures operation near peak efficiency points.

Variable speed drives can further improve efficiency by matching motor output to actual airflow demands. Energy savings of 20-50% are possible with proper speed control.

How do I determine the correct size and airflow capacity for my application when choosing an OEM axial fan motor?

Calculate the required airflow in cubic feet per minute (CFM). Static pressure requirements determine motor power needs.

Fan curves show the relationship between airflow and pressure. Select motors that operate efficiently at the required operating point.

Application-specific factors include ductwork resistance and system pressure drops. High-efficiency axial flow fans can be customized for unique specifications.

What are the common maintenance requirements for axial fan motors with thermal overload protection?

Regular bearing lubrication extends motor life significantly. Inspect thermal protection settings annually to ensure proper operation.

Clean motor housings and fan blades quarterly to maintain airflow efficiency. Check electrical connections for tightness and corrosion.

Monitor operating temperatures during routine inspections. Replace worn bearings before failure occurs to prevent secondary damage.